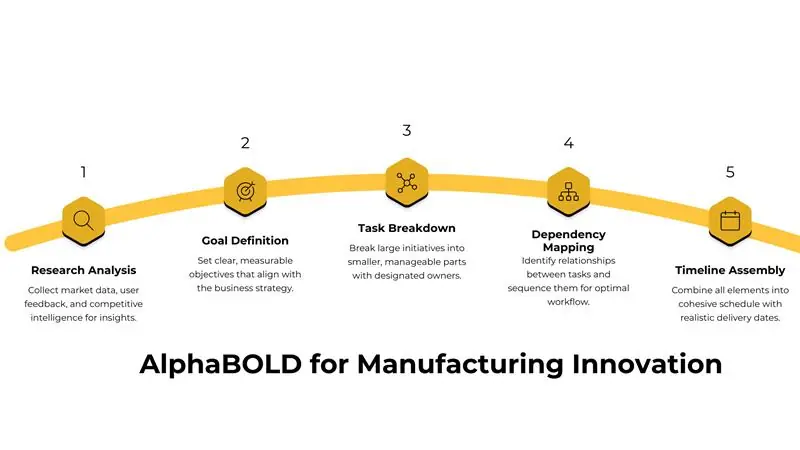

AlphaBOLD supports manufacturers by aligning technology, operations, and data into a cohesive ecosystem that delivers measurable results. Our team understands the realities of modern production environments: volatile demand, complex supply chains, rising cost pressures, and the need for accurate, real-time decisions. We help clients implement and optimize Microsoft Dynamics 365 for Manufacturing through a structured, outcome-focused approach.

Our approach includes:

Modern manufacturers need connected, scalable, and resilient systems to stay competitive. Microsoft’s AI-enabled applications strengthened by AlphaBOLD’s Dynamics 365 consulting services help streamline production, optimize supply chains, strengthen quality control, and support end-to-end operational visibility.

TaylorMade Golf – Manufacturing Execution Visibility

Challenges:

Solution:

Impact:

DCNE – Sales Process and Pipeline Modernization

Challenges:

Solution:

Impact:

JWC Environmental – Dynamics 365 Customer Service Modernization

Challenges:

Solution:

Impact:

AlphaBOLD helps manufacturers improve visibility, streamline operations, and build reliable Dynamics 365 environments that support real-time decision-making. Our team delivers structured implementations, strong governance, and solutions that scale across production, supply chain, sales, and service.