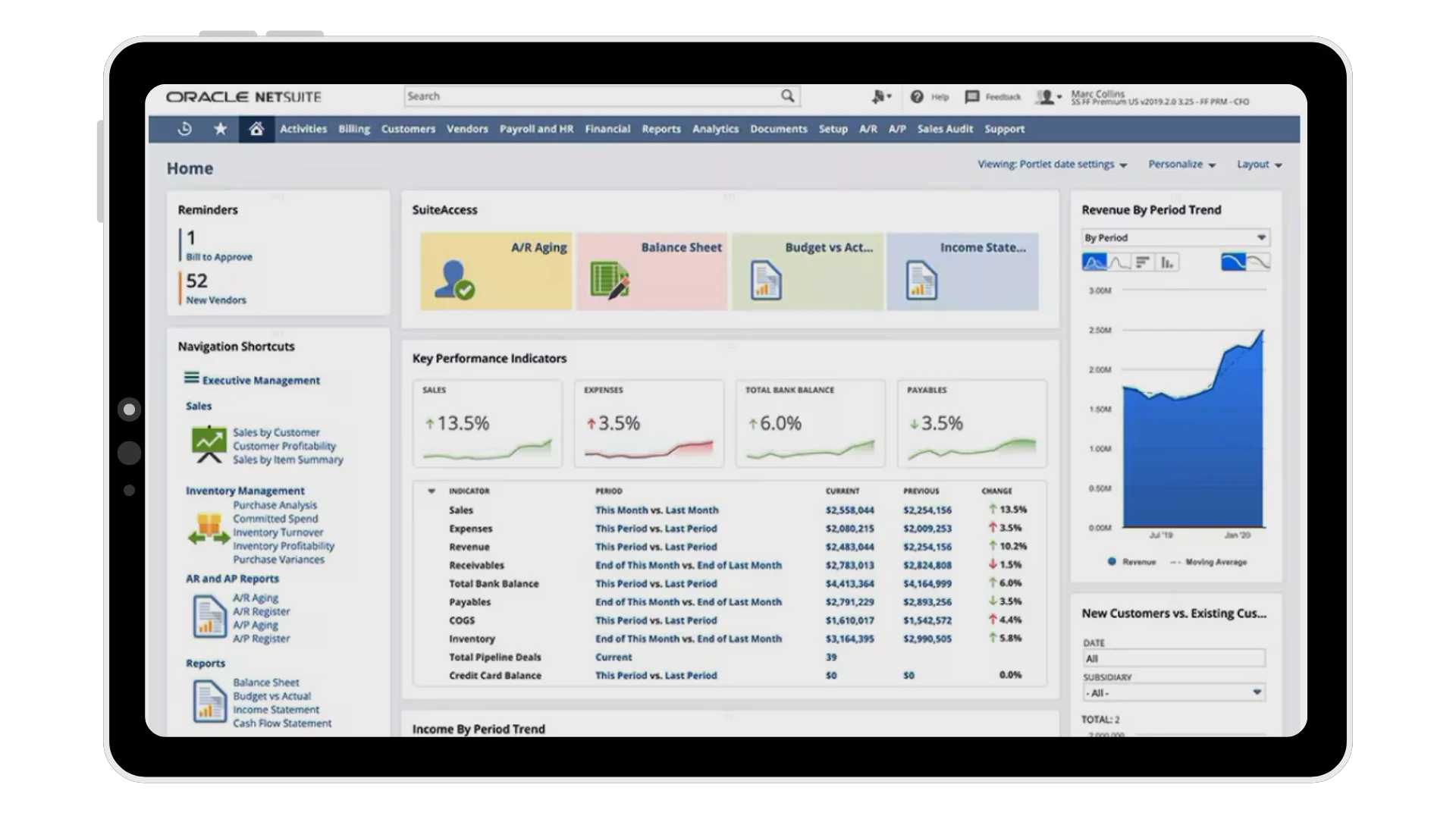

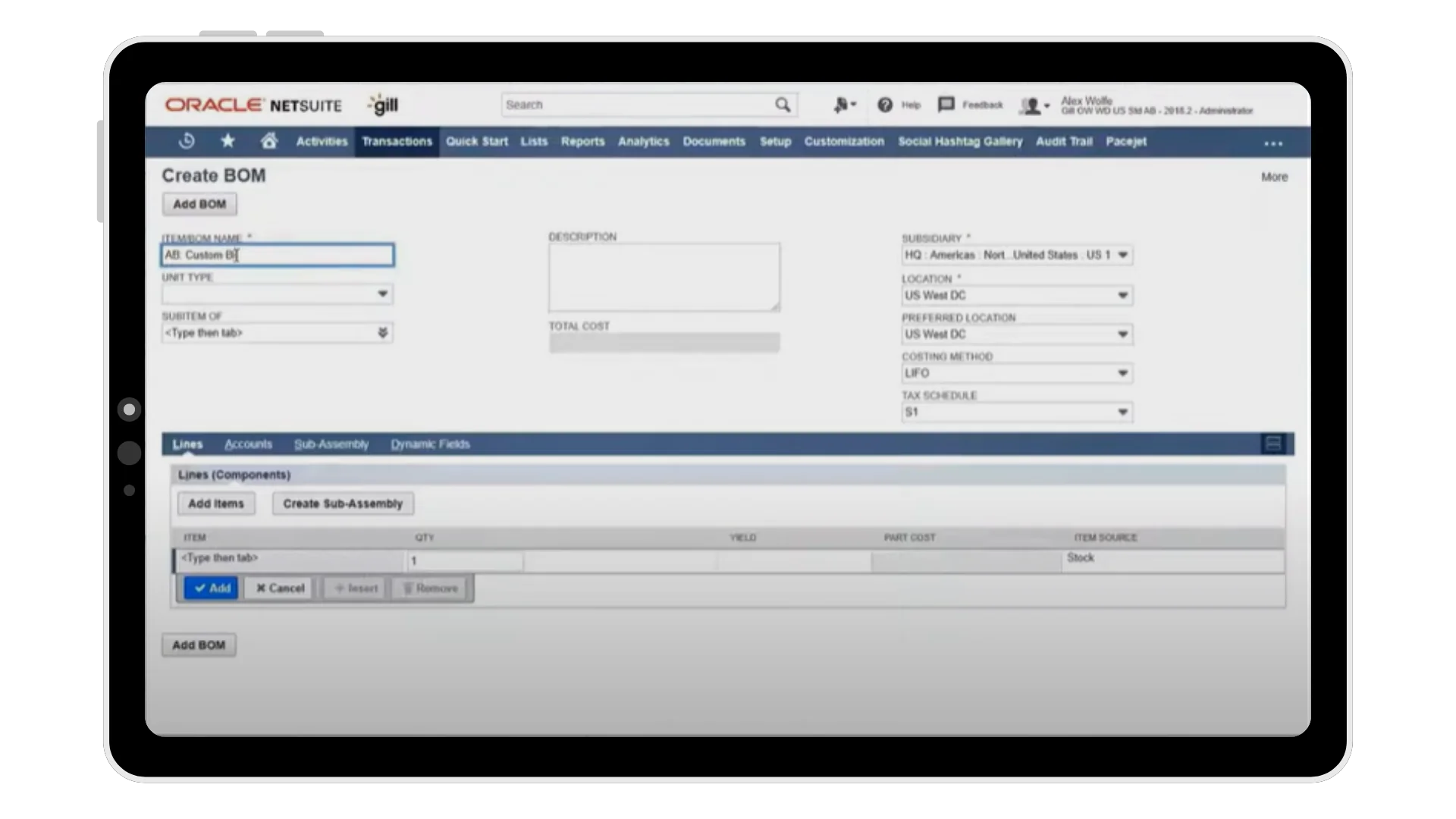

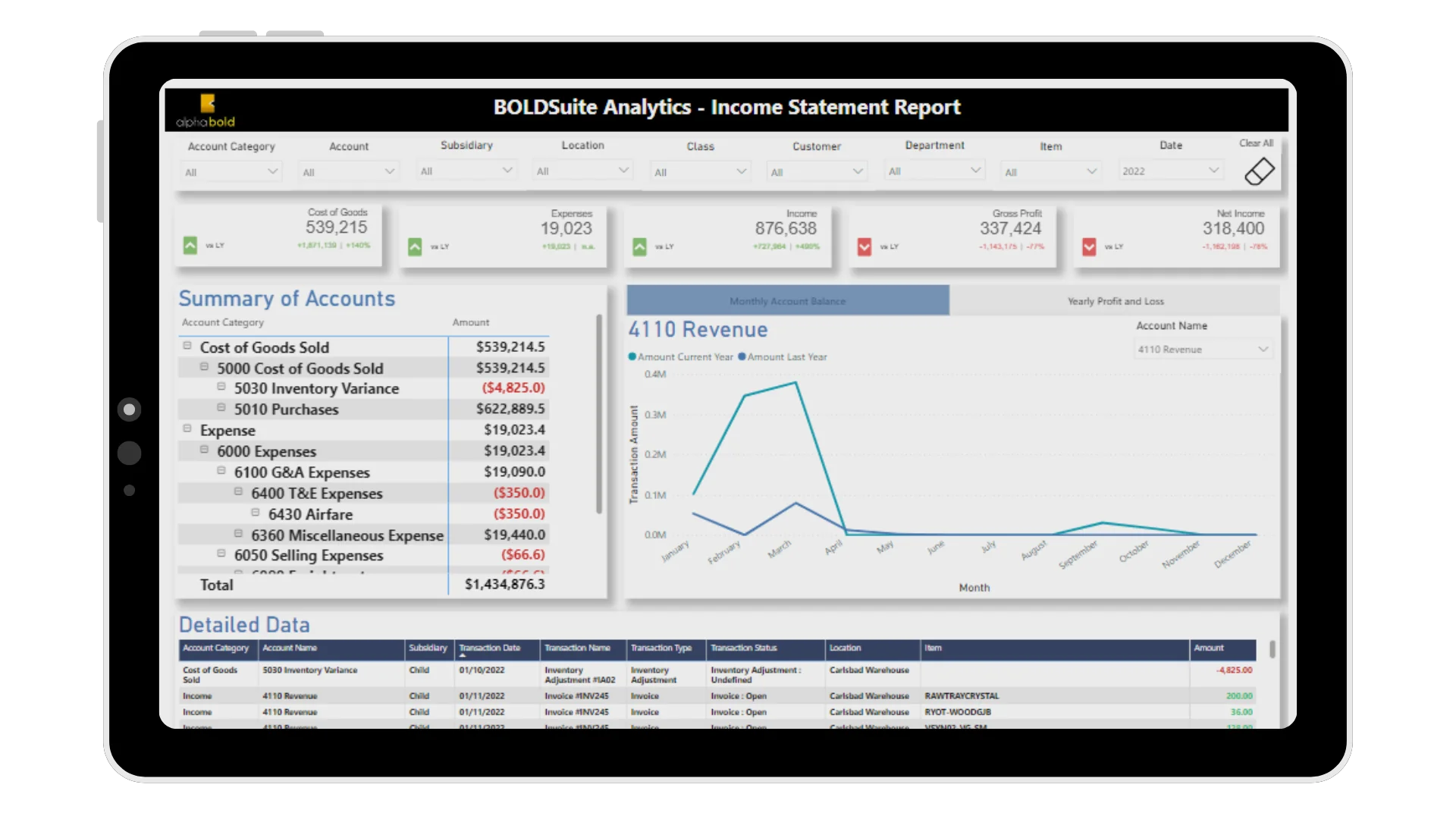

Deploy and configure NetSuite ERP for manufacturing that provides comprehensive manufacturing resource planning, production scheduling, and inventory control capabilities. Our NetSuite manufacturing software implementation includes work order management, capacity planning, routing optimization, and manufacturing cost accounting modules that integrate directly with production floor systems and quality control processes.

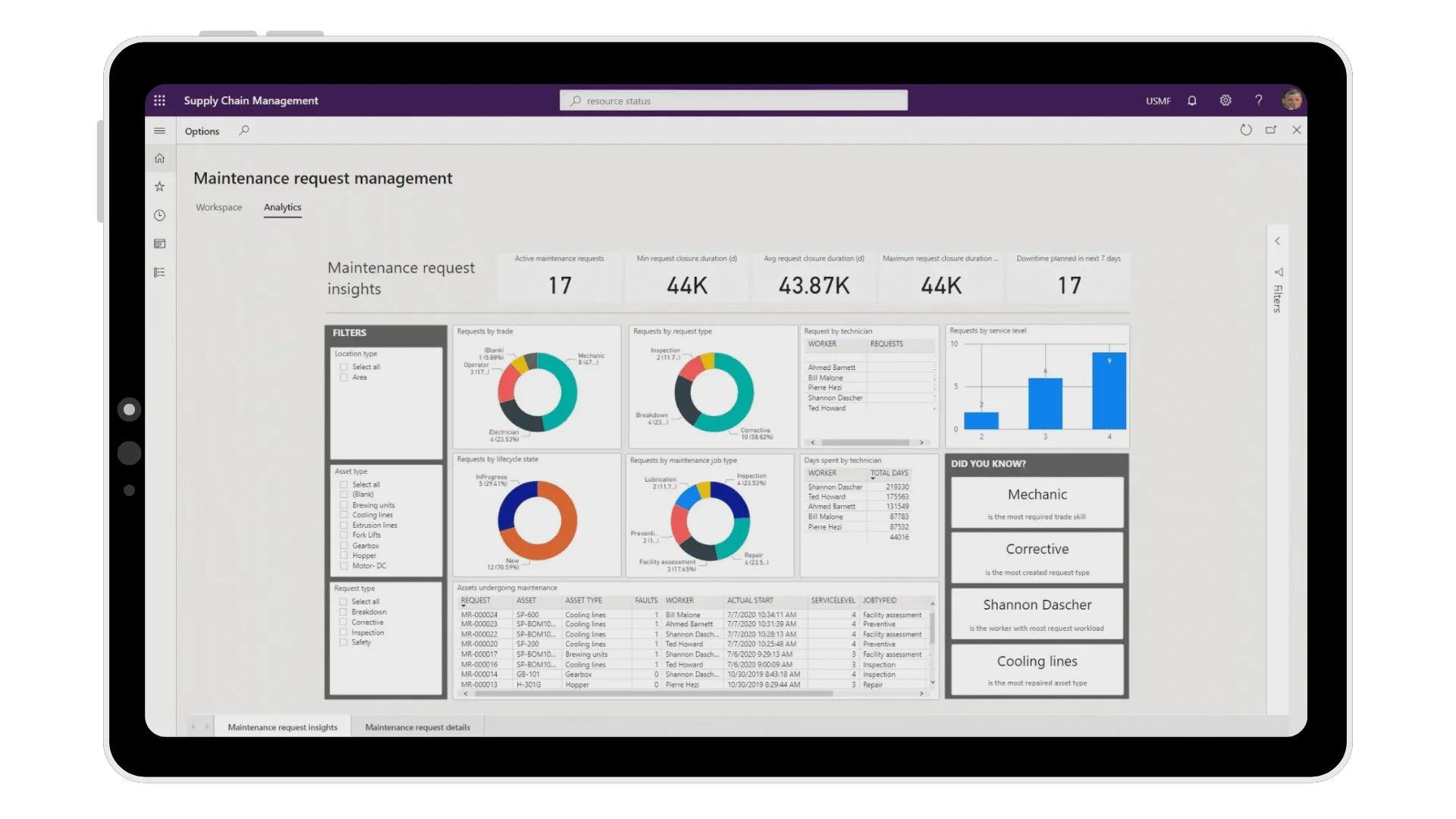

Deploy autonomous agent technology within manufacturing software systems to automate production scheduling, quality control processes, and inventory management tasks. These AI-powered manufacturing software agents monitor production parameters in real-time, automatically adjust manufacturing processes based on quality metrics, and execute preventive maintenance scheduling without manual intervention, improving manufacturing efficiency and reducing production downtime.

Key capabilities of autonomous agents in manufacturing include:

Our solutions go beyond traditional ERP by incorporating AI, IoT, and autonomous agents, offering tailored functionality for production optimization, supply chain visibility, and quality management, which standard ERP systems are not equipped to handle.

The typical timeline for cloud migration ranges from 6-12 months, depending on system complexity. We focus on delivering essential functionalities quickly, ensuring a seamless transition while providing adequate training and system validation.

We follow a phased migration approach, with parallel operations to ensure that critical business functions continue uninterrupted. Our robust testing and 24/7 support ensure smooth transition without significant downtime.

Our clients typically experience 15-30% improvements in operational efficiency, 20-40% reduction in inventory costs, and 25-50% reduction in production downtime within the first year of deployment, resulting in tangible ROI.

Yes, we offer comprehensive support, including system monitoring, performance optimization, user training, and continuous improvement to ensure that your manufacturing systems remain agile and evolve with your business needs.

Explore our insightful blog for thought leadership, industry trends, and practical tips to unlock the full potential of your technology investments.