Introduction

This blog offers crucial advice for manufacturing leaders who want to implement and evaluate the benefits of AI in the manufacturing industry. It emphasizes applications of AI across the entire value chain.

AI in the manufacturing industry has the potential to revolutionize every stage of the value chain. Organizations that have mastered the integration of Artificial Intelligence solutions throughout their entire business reap numerous benefits, including enhanced safety, reduced downtime, 24/7 production, predictive maintenance, direct automation, improved productivity, quality assurance, and faster decision-making.

If you are a leader in the manufacturing industry and have not yet made significant progress in implementing AI, it’s not too late to start. Even though manufacturing is frequently seen at the forefront of deploying new technologies, just 9% of manufacturing executives surveyed by PwC in 26 countries reported using AI in their operations to enhance operational decision-making.

This is most likely because implementing AI is a very difficult, time-consuming, and capital-intensive process that needs a thorough, organized strategy to be effective.

It is now commonly acknowledged that over the next five years, Artificial Intelligence (AI) will significantly influence every business. Businesses that adopt this technology revolution at an early stage will gain enormous advantages that will put them ahead of their rivals, while those that don’t run the danger of losing their competitive advantage.

What Barriers Hinder the Implementation of AI in the Manufacturing Industry?

Before diving into how AI solutions are being used to modernize and advance the global manufacturing sector, it’s important to understand what challenges or risks can stop decision-makers from utilizing AI to its full potential and how to mitigate those risks.

There are several obstacles to overcome when integrating AI into manufacturing operations and practices.

- First off, the hardware and software infrastructure needed to gather and interpret data can be expensive.

- Second, finding prospective employees with AI/Machine Learning (ML) experience and retraining current staff for positions requiring these solutions might be difficult.

- Third, it is not easy to analyze forecast results or to derive and apply actionable intelligence.

- Ultimately, there is an equal likelihood that the deployment of AI/ML technology may not provide a satisfactory return on investment because a few of its features are still in their early stages of development.

Additional Challenges Involve:

Integrating AI solutions into industrial control systems may give rise to unanticipated security risks. Moreover, using computationally intensive AI/ML models may increase manufacturing facilities’ power consumption and environmental footprint.

Lastly, the application of these techniques can assume some of the higher-level decision-making responsibilities, potentially transforming the dynamics of interactions between humans and machines in a manufacturing plant.

But there’s also a lack of comprehension of the results of AI/ML models, a lack of trust in the accuracy of techniques, and behavioral resistance to the cultural shift that bringing AI/ML to manufacturing will bring about.

Moreover, the field of AI/ML continues to grow, which makes implementation difficult, particularly for businesses that are not technology-oriented and lack easy access to necessary technology.

How Are Industries Overcoming Challenges in Adopting AI for Manufacturing?

With constantly advancing research, these areas of concern will be significantly reduced. For instance,

- Sparse datasets can be supplemented with generative models;

- Computing designs for IoT devices that are memory- and power-efficient;

- Appropriate metrics can be developed to measure the degree of confidence in actions made using AI models

- A wide range of automated AI/ML tools that are offered as “Software as a Service (SaaS)” are becoming more widely available, saving individual businesses from having to develop their in-house capabilities.

Want to see how AI is transforming the AEC industry? Here’s everything you need to know: The Revolutionary Impact of AIin the AEC Industry.

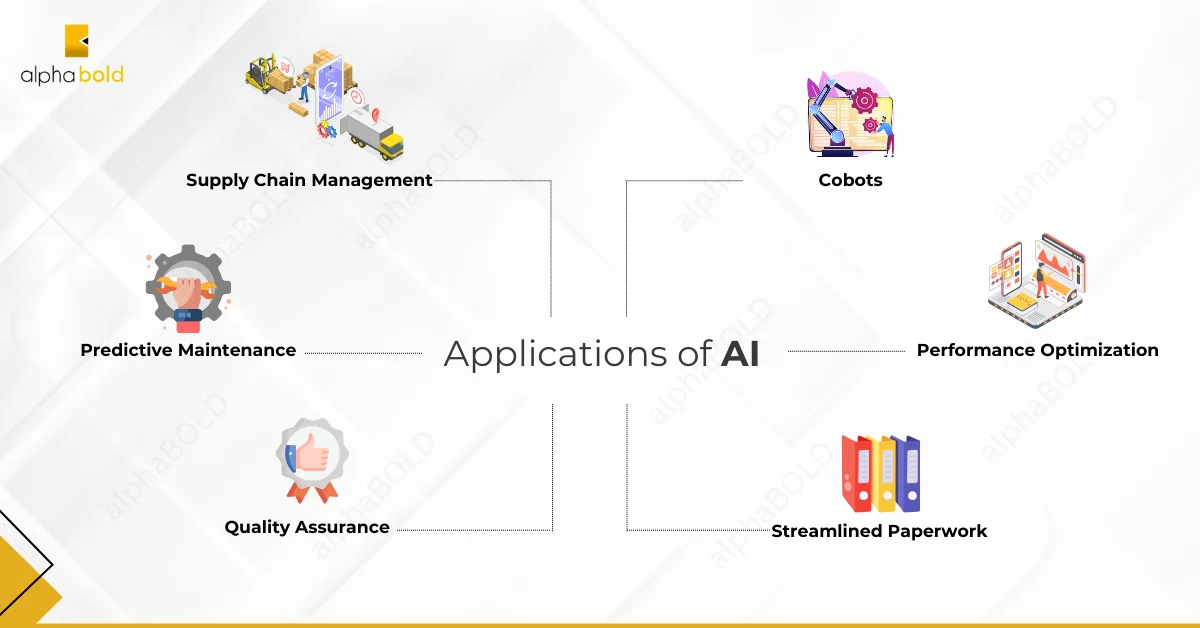

Applications of AI: How Is AI Used in Manufacturing?

You’ll be amazed at the amount of AI applications and uses in the manufacturing industry. In addition to digging into each use case, we’ll concentrate on the market potential of these use cases and see real-world examples of where these AI applications are being used.

1. Supply Chain Management:

Thirty percent of companies are using AI solutions to handle their retail chain operations and accountancy. Manufacturing facilities frequently experience interruptions in their supply chains. The manufacturing sector has seen significant upheaval due to the use of AI. A factory can change its procedures to increase accuracy, cost-effectiveness, and efficiency by utilizing AI tools and algorithms.

AI is being used in manufacturing to improve inventory management, improve forecasting of demand, streamline logistics, and use data analytics to improve performance. Machine Learning algorithms enable businesses to analyze all data, identify trends, and predict changes in demand.

2. Cobots:

AI’s contribution to the overall robotics industry is projected to grow to 10.72 billion USD in 2024 and 20.64 billion USD in market value by 2030.

Cobots, or collaborative robots, are a relatively new concept in the manufacturing industry. Picking and packaging are made easier at fulfillment centers by the use of AI-driven technology. Additionally, cobots operate concurrently with workers and use an AI system integrated into them to recognize items.

Cobots illustrate the significant influence AI has had on industries such as manufacturing. They execute intricate jobs, exhibit precision and promptness, manage difficult assembly line operations, and conduct quality assurance assessments. These robotic resources are now indispensable when it comes to lowering maintenance costs or avoiding downtime.

3. Predictive Maintenance:

When a failure is accurately predicted, workers can quickly reallocate production loads to other machines while repairing the malfunctioning devices. Approximately 40% of repair expenditures are retained by this preventive maintenance.

Smart factories use modern predictive analytics and machine learning algorithms as part of their AI manufacturing strategy. This permits a manufacturer to foresee and dynamically screen for machine faults, decreasing potential downtime and allowing them to work within an efficient maintenance schedule.

By capturing and analyzing data, simulating asset behavior in a virtual equipment setting, and enforcing a digital twin—a virtualized version of an actual engine—staff members in manufacturing can benefit from artificial intelligence.

The Ford plant gained popularity for implementing digital twins as a component of its digital transformation initiative. Twins help improve manufacturing line performance, fault detention, and energy loss detection.

Bonus read: Introduction to Predictive Maintenance Solution.

Empower your Business with our Specialized AI Solutions!

Use our expert AI manufacturing services to grow your company and address the issues you deal with daily. We are eager to learn more about your needs and provide practical and affordable manufacturing solutions. Reach out to us right now to hear directly from our successful projects working with companies just like yours.

Request a Consultation4. Performance Optimization:

Using AI to optimize performance is another innovative idea. By limiting decision-making to data-supported options, AI algorithms assist in maximizing machinery effectiveness overall, optimizing operations, and minimizing downtime.

Artificial intelligence users in manufacturing reported 4%–5% increases in EBITA and a 10%–15% improvement in production efficiency.

General Electric and its AI algorithms are a good example of this application of AI as they were created to evaluate enormous data sets, both past records and current data sets. Artificial Intelligence (AI) helps manufacturers like General Electric by providing real-time trend analysis, forecasting equipment problems, increasing equipment efficiency, and optimizing the effectiveness of machinery.

5. Quality Assurance:

According to an interview, 60% of industrialists who used AI tools for quality monitoring were able to identify 200% more supply chain errors than they were able to do before implementing AI in their manufacturing processes.

AI has completely changed how organizations approach quality control in the manufacturing industry. Following the implementation of AI, alignment and accuracy levels have increased significantly. When using artificial intelligence, manufacturers utilize computer vision algorithms to examine images and videos of items and their components.

Algorithms that are executed with exceptional accuracy identify irregularities, flaws, or outliers from the normal range of quality. AI vastly outclasses human abilities in this context. Algorithms also make it easier to fix errors by evaluating past data, enabling producers to take corrective action before any effect.

6. Streamlined Paperwork:

Paperless production helps you replace printed paperwork with digital records, which increases real-time visibility and product quality. Four manufacturers out of six have already made the transition to digital recordkeeping.

Two major trends in the manufacturing business are the use of Robotic Process Automation (RPA) to automate administrative tasks and the deployment of sophisticated machine learning algorithms in production. In the past, manufacturing involved a lot of paperwork, including purchase orders, invoices, and quality control reports. To increase industrial productivity, the majority of labor-intensive, error-prone, and manual operations were replaced by AI in manufacturing.

Firms utilize AI-enabled intelligent bots to autonomously gather data, extract it from documents, and classify and categorize it before entering it into suitable systems. The majority of repetitive or rule-based operations are completed accurately and efficiently by RPA bots.

The Future of AI in the Manufacturing Industry

Artificial intelligence in manufacturing appears to have a bright future. First off, AI in the manufacturing industry will be most valuable in three key directions:

- AI promises to revolutionize factory and plant operations. Cutting-edge innovations that bring data from equipment into one location, integrate it, and move it into settings where it will be mixed with other data will soon increase the effectiveness of traditional production.

- Artificial Intelligence will drive decision-making. Data cooperation is anticipated to become commonplace in the next years, involving collecting and fusing information from many teams and empowering specialists to offer distinctive perspectives.

- Data strategies with a forward-looking approach will become essential. It will also become standard practice to combine, store, control, and manage data on a single platform to support flexibility and modifications to a competitive climate that is changing fast.

The following statistical analysis and forecasts might help you realize the potential impact of artificial intelligence on the manufacturing sector:

- 30% of labor hours are predicted to be automated by generative AI by 2030.

- Forecasting errors could see a 20% decrease by 2025.

- AI is predicted to reduce costs by 2.6 trillion USD and save 1.3 trillion USD over the next ten years.

- AI technology will contribute to a 40% increase in manufacturing and production by 2035.

Expert AI Solutions for the Manufacturing Industry with AlphaBOLD

Finding artificial intelligence solutions for challenging business issues is our primary goal at AlphaBOLD so we can positively influence how our customers experience technology. By combining AI with our current solutions, we can now automate business activities that formerly required human interaction. A solution partner like AlphaBOLD, who is well-versed in AI solutions, can make all the difference when it comes to installing new solutions for your business processes. We offer AI solutions to healthcare, manufacturing, and food and beverage industries.

Explore AI Solutions for Manufacturing with AlphaBOLD!

Prevent downtime and reduce costs with our predictive maintenance AI solutions. By anticipating equipment failures and calculating MTTF, our models help you plan maintenance efficiently. See the benefits of integrating these solutions with your existing ERP and CRM systems. Get in touch to revolutionize your manufacturing processes.

Request a ConsultationConclusion

You can see that artificial intelligence finds a wide range of applications in the manufacturing sector. In fact, very few industries would find it reckless to adopt AI. Companies keen to solve present production problems and keep up with their competitors are now considering the benefits and drawbacks of implementing AI in the manufacturing industry processes.

Explore Recent Blog Posts