Predictive Maintenance in Manufacturing

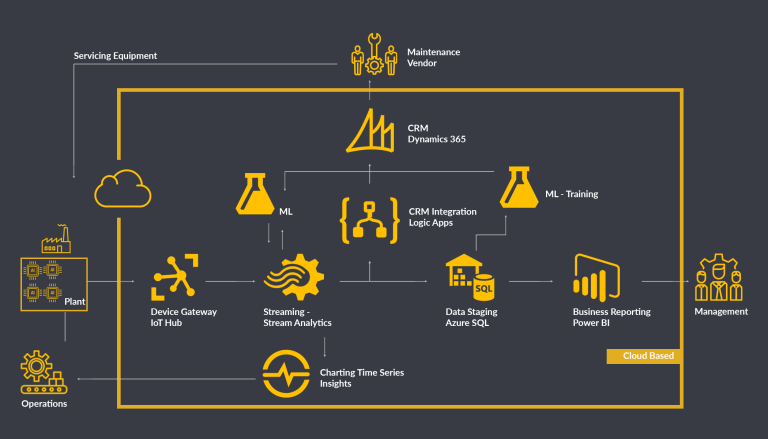

Talking devices is AlphaBOLD’s initiative to envision a smarter world where devices could effectively communicate to systems and humans. The information shared by talking devices, through sensors, can be used to measure device health. This can change the way industries operate by providing operational efficiency, minimizing maintenance costs, and providing valuable business insights.

BOLDConnect is an end-to-end predictive maintenance solution that uses artificial intelligence and smart sensors to improve operational efficiency, minimize costs, and extend the equipment lifecycle. By connecting IoT devices with business processes, you can monitor the health and performance of your industrial equipment anytime, anywhere.

BOLDConnect uses specialized sensors to retrieve telemetry data from manufacturing equipment in a non-invasive manner. This data is processed using an AI solution to schedule equipment maintenance by predicting equipment breakdowns.

Increase Production

Optimize equipment performance to increase production capacity

Reduce Downtime

Schedule preemptive maintenance through real-time insights on equipment health

Production Planning

Get insights on your production capacity by calculating performance capacity of each unit

Minimize Power Loss

Optimize equipment to reduce power wastage and electricity bills

Real-time Performance Analytics

Power BI visualizations to analyze equipment health, performance, forecast maintenance, and fiscal planning

Fault Determination and Classification

Get real time notifications on location and nature of faults

You Can Benefit From Our Experience

We can help you solve your business problems and reduce your pain points. We can estimate a budget to build your solution based on experience with similar projects. Get in touch today!

Latest From Experts

INTRODUCTION TO PREDICTIVE MAINTENANCE SOLUTION

In order to maintain your machinery with a conductive-driven program, read this detailed guide on predictive maintenance.

WEBINAR: IMPACT OF IIOT PREDICTIVE MAINTENANCE ON MANUFACTURING AND PRODUCTION QUALITY

Watch how AlphaBOLD and Microsoft can help transform the way you do manufacturing!